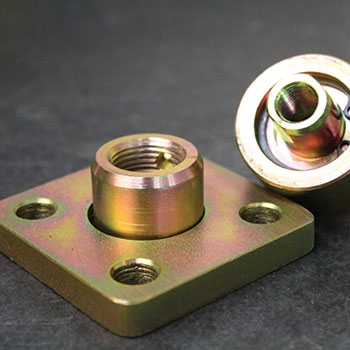

Available Styles

Where air or hydraulic cylinders are designed to drive a machine slide, this question should always be asked: If the machine deflects under load, or the installation or maintenance mechanic does a less-than-perfect job of alignment, what will this do to slide actions?

The answer is usually “Nothing” for clevis or trunnion mounted cylinders. But where space, mounting requirements or length of stroke rule out the clevis type mount, then trouble can develop. Installation inaccuracy, subsequent wear of slide bearings, or deflection under gravity and operating loads can throw a heavy side load on the cylinder rod as it passes through the gland. Results are likely to be:

- Binding of rod, with jerky action or stalling under load.

- Excessive wear of gland, causing leaks.

- Excessive downtime.

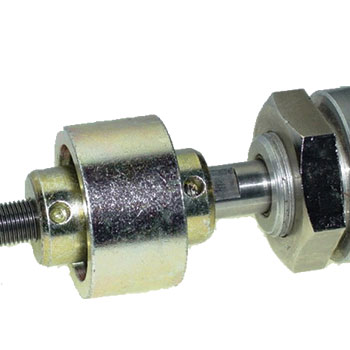

The Gagne Rod-End Coupling is designed to correct this problem at the source by transmitting the push-pull cylinder force bet relieving all side forces (under usual conditions). Lateral Displacement: The Coupling is designed to accept up to 1/32 inch error in the smaller sizes, more in the larger sizes. Angular Displacement: The Coupling will operate freely even though misaligned as much as 1 degree.

Costs

Many designers recognize this 4-bearing problem during design and provide their own special automatic adjusting device. But costs of the “homemade” product will include some of all of these factors. Costs eliminated by purchased couplings:

- Design and detailing time.

- High shop costs for a custom machined device.

- Excessive maintenance if the new design has been less than perfect.

- Reduces down time.

Thrust Capacity

All parts in Gagne couplings are steel, and the couplings will accept in “push” the full shear strength of the cylinder rod thread. The “pull” strength of the Type “A” Flange Coupling is determined by other components, such as the mounting bolts or the cylinder rod thread (normally this is many times the force which the fluid can exert on the piston). The “pull” strength of the Type “B” and “C” Couplings is determined by the shear strength of the heavy-duty snap ring, which is listed in the chart at right.

Sizes

Thread sizes are regularly offered to fit all standard air and hydraulic cylinders within the range of ordinary use. Larger sizes or special borings will be quoted on request, including metric threads and stainless steel couplings.